Ruggedized Display Assemblies for Mission-Critical Environments

Engineered for Performance. Built for the Extreme.

Ruggedized Display Assemblies for Mission-Critical Environments

Engineered for Performance. Built for the Extreme.

At ProtoLogic

we specialize in the design, qualification, certification, and manufacturing of ruggedized Display Assemblies tailored for the most demanding applications in Avionics, Defense, and Industrial sectors. When performance, reliability, and survivability are non-negotiable, our display solutions deliver.

Our Capabilities

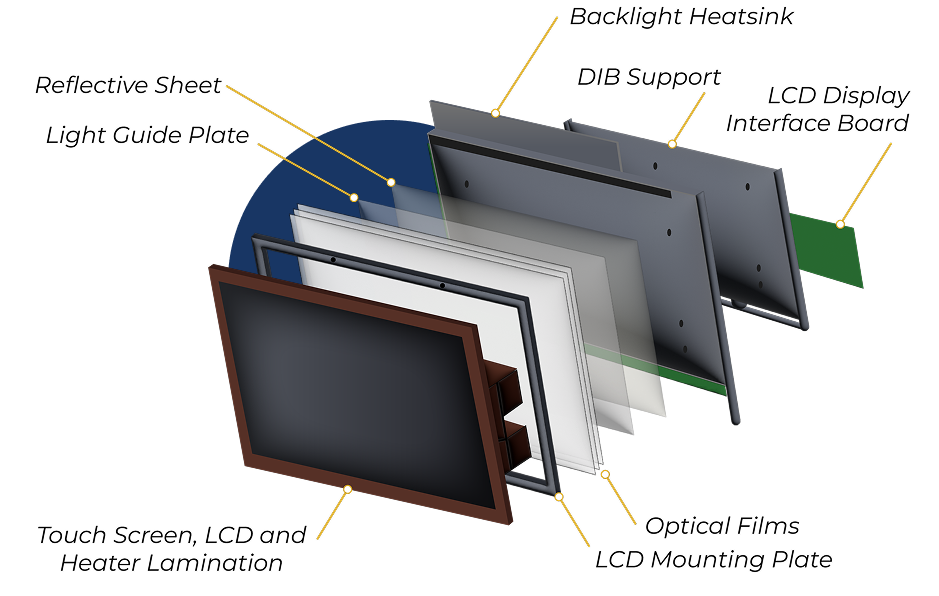

Custom Display Design

- Complete lifecycle control from concept through sustainment

- Industrial COTS LCD, Semi-Custom LCD and Fully Custom LCD

- High-brightness and dual-mode operation NVIS-compatible backlight designs. Closed loop backlight monitoring to ensure lifetime performance

Environmental Qualification & Testing

- MIL-STD-810, DO-160, and other rigorous standards

- Shock, vibration, temperature, humidity, and altitude resistance

- EMI/EMC shielding and compliance

Certification Expertise

- Certification to DO-254 and DO-178C standards

- Experience across commercial, military, aerospace, and other industrial platforms

- Close collaboration with DERs and regulatory bodies

Scalable Rugged Manufacturing

- AS9100/ISO 9001 certified quality system

- Made in the USA! In-house optical bonding, final assembly, integration, acceptance testing and quality assurance

- Supporting everything from rapid prototyping through high volume production

Key Features

Engineered

Ruggedness

Designed to meet or exceed MIL-STD-810, DO-160, and IEC 60068 standards

High shock, vibration, and impact resistance

Wide operating temperature ranges (-40°C to +85°C)

Sunlight-Readable

Displays

High brightness

(300+ fL Available)

Advanced optical bonding for enhanced contrast and clarity

Anti-reflective, anti-glare, and anti-fingerprint coatings capable of <1% Specular and <0.1% Diffuse Reflection.

Night Vision

Compatibility

Dual-Mode (Day / Night) NVIS-compliant backlighting options

Multiple dimming modes for day/night operation

Seamless transition between lighting environments

User-Friendly

Interfaces

Multi-touch, glove-compatible touchscreens

Best-in-class touch performance through integration with Baanto’s ShadowSense touch technology

Customizable user interface elements

EMI/EMC

Protection

Shielded designs to minimize electromagnetic interference

Compliant with MIL-STD-461 and RTCA DO-160 EMI standards

Sealed & Weatherproof

Corrosion-resistant materials and coatings

Conformal coating for PCB protection in humid or corrosive environments

Washdown and Immersion Compliant solutions

Modular and Configurable

Smart & Connected

Long Life Cycle Support

Mission-Ready Reliability

Built to Survive.

Designed to Excel.

Whether it’s a cockpit display in a supersonic jet, a tactical ground vehicle interface, or an industrial control panel in an extreme environment, ProtoLogic EDS delivers solutions engineered to survive and thrive where others fail.

Applications:

Military & Defense Systems Avionics & Flight Deck Displays Ground and Naval Platforms Rail and Industrial Automotive Mission-Critical HMI Systems

Why

Choose

ProtoLogic?

Vertically Integrated

From concept to certification and into sustainment – all under one roof.

Field-Proven Reliability

Trusted across defense, aerospace, and industrial sectors.

Agile & Collaborative

Engineering excellence tailored to your requirements.

Why

Choose

Protologic?

Vertically Integrated

From concept to certification and into sustainment – all under one roof.

Field-Proven Reliability

Trusted across defense, aerospace, and industrial sectors.

Agile & Collaborative

Engineering excellence tailored to your requirements.

Let’s Build What’s Next

Looking for a partner who understands the high-stakes nature of your environment?

ProtoLogic EDS is ready to take on your toughest display challenges.